Where forging Uses

Forging Cycles

Forging Cycles

- Upto 1150°C for Steel

- 360 to 520°C for Al-Alloy

- 700 to 800°C for Cu-Alloy

Cold Forging

Cold forging distorts metal while it is beneath its recrystallization point. Cold forging increments rigidity some and yield strength considerably while decreasing pliability. Cold forging generally happens close to room temperature. The most widely recognized metals in chilly producing applications are normally standard or carbon compound prepares. Cold forging is ordinarily a shut pass on process.

Manufacturers might pick cold forging over hot forging for various reasons — since cold produced parts require very little or no completing work, that step of the creation cycle is frequently unimportant, which recoveries costs. Cold forging is likewise less defenseless to tainting issues, and the last part includes a superior in general surface completion.

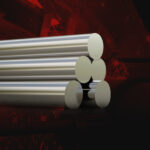

At KESRI ALLOYS, manufactures carbon steel, alloy steel, and stainless-steel forged bars of various thicknesses and dimensions to meet industrial requirements. Most commonly, the length is 6 meters, but it can vary between 3.5 and 12 meters. Each and every Forged Bar which is manufactured at Kesri Alloys undergoes a rigorous inspection procedure to ensure that our clients get the finest quality.