A common question we receive is how hot rolled steel differs from cold rolled steel. Here’s take a look at the difference between Hot Rolled Steel and Cold Rolled Steel what you need to know!

Hot Rolled Steel

Hot rolled steel is less complicated to create, to form and type & its supply in a very mill method involving rolling the steel at extreme temperature. It starts from a chunk of still billet that is heated 1700 degrees Fahrenheit (926° Celsius) so the steel is rolled through the mill into the actual form. The entire method is completed at extreme temperature and at the tip is being cooled down. The cooling down might cause the steel to shrink and thus there’s less management over the ultimate size and form.

Hot rolled steel is often used once precise shapes and tolerances aren’t essential.

Advantages –

- Easier to make: heat it up, erupt, relax and that’s it!

- Cheaper than cold rolled

- Most well-liked shapes area unit hot-rolled (UC, UB, SHS, RHS, PFC, flats etc.)

- Hot rolled steel is allowed to cool down at room temperature and it’s free from internal stresses that may arise from conclusion or work-hardening processes

Disadvantages –

- Dimensional imperfections caused by cooling down (shrink, warpage) and heating (expanding)

- Rough texture on a surface, got to be removed and buffed before painting

- Slight distortions

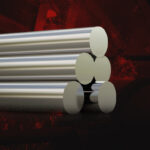

Cold Rolled Steel

Cold-rolled steel is a versatile and highly sought-after material in various industries. Its unique manufacturing process involves passing hot-rolled steel through a series of rollers at room temperature. This technique not only enhances the steel’s surface finish but also improves its dimensional accuracy and mechanical properties. The resulting cold-rolled steel exhibits exceptional strength, durability, and a smooth surface, making it ideal for a wide range of applications.

Advantages –

- Correct form (consistent and straight)

- A wider vary of surface finishes

- A sleek and shinier surface

- Bars square measure true and sq. and have well-defined edges and corners

- Tubes have higher coaxal uniformity and straightness.

Disadvantages –

- Costlier

- Fewer shapes obtainable cold-rolled (sheets, box section shapes: CHS, SHS, RHS)

- Extra treatments will produce internal stress inside the material; this may cause unpredictable distortion if the steel isn’t stress mitigated before cutting, grinding, or welding.

How to differentiate them?

Hot rolled steel comes with a scaly surface, slightly rounded edges and corners and also the surface is non-oily. Cold rolled steel has Associate in Nursing oily or greasy end, swish surface, and really sharp edges.

For Any Product Related Queries

Contact Us Now

+91 9810 112 977